- Steel Sheets[2]

- Sheet Metal Fabrication[1]

- Steel Wire Mesh[10]

- Speakers[1]

- Filter Meshes[2]

- Acoustic Panels[1]

- HVAC Systems & Parts[1]

- Metal Building Materials[10]

- Ceiling Tiles[1]

- Other Furniture[1]

- Curtain Walls[1]

- Other Metals & Metal Products[1]

- Stainless Steel Sheets[1]

- Fencing[4]

- Barbed Wire[1]

- Door & Window Screens[1]

- BBQ Grills[1]

- Pet Cages[1]

- Conveyors[1]

- Contact Person : Ms. cheng julie

- Company Name : Suzhou Baishuo CNC Screen Co., Ltd.

- Tel : 86-0512-57314448-806

- Address : Jiangsu,kunshan,NO.1033, Yingbin Middle Road

- Country/Region : China

- Zip : 215300

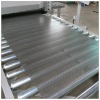

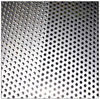

Perforated Galvanized Plate

Perforated Galvanized Plate

Specification

Material: galvanized plate

Specification & Size: Customization, metal sheet thickness 0.1mm—15mm

Hole pattern: Round hole, square hole, oblong hole, groove hole, triangle hole, hexagon hole, octagon hole, pattern hole or specified special hole.

Hole diameter, center distance: Metal sheet 0.1mm—200mm, center distance specified by customer or recommended by us.

Perforation mode: Straight, 45°, 60° staggered pattern

Reprocessing: Bending, rolling, welding, cutting or specified by customers

Margin: No limit, general margin or special customer demands

Perforated Galvanized Plate is one of most widely used metal materials in the world and a raw material mostly used by Byso for perforated metal sheet production.

A layer of metallic zinc is coated on steel sheet surface to prevent steel sheet surface from being corroded and prolong service life, the zinc coated steel sheet is called galvanized sheet. Galvanized sheet strip steel products are mainly used for architecture, light industry, automobile, agriculture, livestock, fishery, commerce and other industries.

It is divided into the following types according to production and processing method:

(1) Hot dip galvanized steel sheet: Thin steel sheet made by dipping thin steel sheet in a dissolved zinc tank to make its surface adhere with a layer of zinc. It is mainly produced by continuous galvanizing process, namely continuously dipping rolled steel sheet in a dissolved zinc tank to make galvanized steel sheet;

(2) Alloying galvanized steel sheet: The steel sheet is also made by a hot dipping method, but it should be heated to 500°C or so after tapping to generate zinc and iron alloy envelope. The galvanized sheet has good coating adhesion and weldability;

(3) Electrogalvanized steel sheet. Galvanized steel sheet made by electroplating process has good processability. But coating is very thin and not anti-corrosive than hot dipped galvanized sheet;

(4) One-side and two-side galvanized steel sheet. One-side galvanized steel sheet, referring to one-side galvanized product, has better adaptability in welding, coating, rust prevention and processing than two-side galvanized sheet. To overcome the defect of a non-galvanized side, the other side is coated with thin zinc to form two-side galvanized sheet;

(5) Alloying, composite galvanized steel sheet: Alloying and composition plating steel sheet made of zinc and other metals, such as lead and zinc. The steel sheet has excellent antirust property and good coating property.

Besides, it also includes color galvanized steel sheet, printing coated galvanized steel sheet, PVC lamination galvanized steel sheet, etc. The most common is hot dip galvanized steel sheet.

Because of different processing modes in coating process, galvanized sheet shows different surface states, such as common spangles, fine spangles, smooth spangles, zero spangle and parkerized surface.

Perforated Galvanized Plate